The technical specification IEC 62046

Safety of machinery – Application of protective equipment to detect the presence of persons

This technical specification provides recommendations for the installation and use of ESPEs.

It is therefore mainly applied to Safety light curtains and Safety Laser Scanners, Safety Mats.

This technical specification meets the needs of the machine manufacturers and of the machine users. Indeed it gives requirements for the selection of the most suitable model, its correct positioning and its correct interfacing to the machine.

Selection process

The purpose of the Selection Process of the Protective Device (ESPE) is to ensure that, through proper choice and application of the device (and if necessary through the integration of other safety measures) the risk of injury to the operator is reduced to the acceptable minimum.

In order to make a correct choice, the following factors must be taken into account which may adversely affect the effectiveness of protection:

- Machine characteristics

- Environmental characteristics

- Hhuman characteristics

- Type of use of the protective equipment

Pprotective equipment characteristics.

Machine characteristics

For optoelectronic safety devices to be effective, it is necessary to verify that they are suitable for the shape and size of the detection zone (e.g. width and height of the access area).

However, some characteristics of particular machines can preclude the use of protective equipment as the sole protective measure.

Examples of these machine characteristics are:

- Possibility that the machinery will eject materials, swarf or component parts

- Risk of injury from thermal or other radiation

- Unacceptable noise levels

- An environment likely to adversely affect the function of the protective equipment

- A material being processed that can influence the effectiveness of the protective measure

- It is impossible to stop the machine immediately when it is started because this could introduce additional risks or because the machine can only be stopped at the end of the processing cycle due to the particular type of operation

Or the ESPE is poorly efficient if:

- The machine stopping time is unknown or is randomly variable due to unquantifiable delays introduced by the control circuit or due to under dimensioned braking systems

- The machine cannot be stopped at any point in its working cycle

Environmental characteristics

Care must be taken to assess the environment in which the machine is expected to work. Before choosing the device, all the necessary information about the working environment and the possible variations that are reasonable to expect during the life of the machine should be available.

A non-exhaustive list of environmental conditions that may adversely affect the operation of an optoelectronic device are as follows.

- Electromagnetic interference

- electrostatic discharge

- radio frequency interference, for example mobile telephones

- lightnings

- Vibration/shock

- Light interference

- ambient light

- reflective surfaces

- infra-red, for example remote controls or other ESPEs that can emit interfering light

- Pollution

- water

- dust

- corrosive chemicals

- smoke

- Temperature

- Humidity

- Weather conditions

- Radiation

If there are special operating conditions such as outdoor operation (fog, rain, snow) or operation in potentially explosive or flammable atmospheres (paints, sawdust), then further environmental requirements may be needed that will normally have to be agreed upon with the manufacturer of the device.

Dimensions and characteristics of the human body

Since the main function of the ESPE is to detect the human body or parts of the human body, it should be taken into account its anatomy (fingers, hands, legs), the predictable maximum speed, how it interact with the machine.

The resolution, that is, the detectable minimum object, must be the function of the body part to be protected (eg fingers, hands, legs, arms). Typically, this choice is made by referring to the ESPE manufacturer’s catalog or user manual.

Uses of protective equipment

A protective equipment may be used to provide:

- Trip function

- Presence sensing function

- Combination trip function and presence sensing function

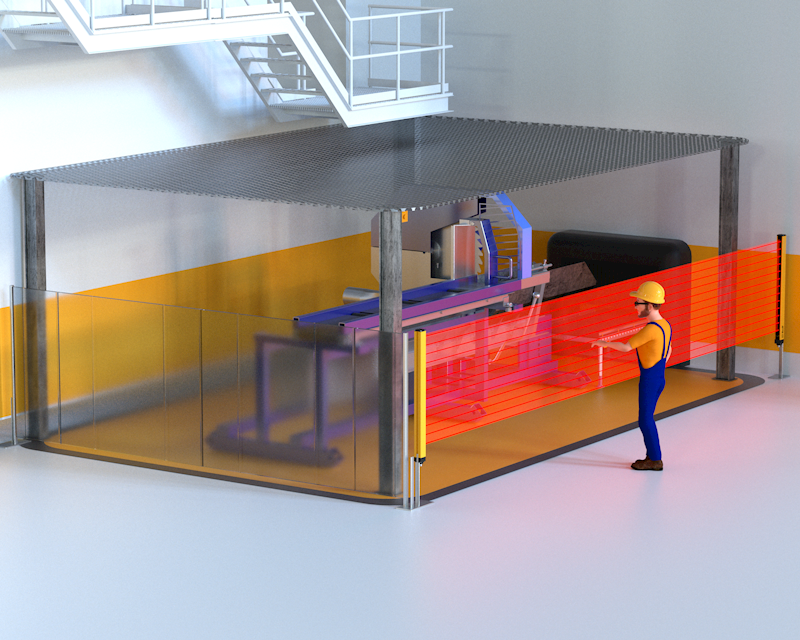

Use of an ESPE for Trip function

Where the protective equipment is used to provide a trip function, it shall be positioned at a sufficient distance from the specific machine hazard(s) to ensure the machine can stop or otherwise reach a safe condition before any part of an approaching person can reach the hazard zone.

This safety distance shall take into account:

- Protective equipment detection capability in relation to human characteristics

- Approach speed

- Body part penetration/encroachment

- Rreaching over or under the sensing zone

- Ppossibility of circumvention

- The response time of the ESPE

- The stopping time of the machine measured under the worst operating conditions (maximum load, maximum speed, any factors that may lead to deterioration of the braking performance, low temperatures etc.)

- Any reflective surfaces that could, under certain conditions, generate an optical bypass of the beams and consequently prevent the detection of the person

The minimum distance shall be maintained for all foreseeable directions of approach considering also the furthest extension of the moving part towards the direction of approach.