Safety laser scanner

Characteristic elements

The Laser scanner (Active Opto-electronic Protective Device responsive to Diffuse Reflection) measures the distance between the objects that fall into its sensing field by means of the small fraction of energy that is re-diffused by the objects themselves in axis with the direction of emission.

AOPDDRs do not need a cooperating target for their operation, especially where the protected area is mobile, as is the case with AGVs, or where it is necessary to vary the position and size of the protected area during the production process.

- For EN 61496-3, Laser Scanners must be classified in accordance to type 3 or lower safety sensors.

- For IEC 61508, IEC 62061, ISO 13849-1, they must be used to realize safety functions up to SIL 2 – PL d or lower.

Using the Safety Laser Sensor, precise programmable horizontal protected areas of variable shape can be created (i. e. semi-circular, rectangular or segmented), suitable for all applications with no need of a separate reflective or receiving element.

It is also possible to use the Laser Scanner in a vertical position for the access protection to a dangerous area, in that case detection of the edge of the gate is mandatory (IEC TS 62046).

Any person or object entering or remaining in the safety zone during survey causes, through the self-monitored static safety outputs of the device, an emergency stop command to the control system of the protected machine. The machine’s hazardous movement will thus be interrupted.

If the warning zone is instead occupied, thanks to a non-safety dedicated solid state output, a signal is sent to the machine control system, which can be used to activate a light or a sound signal in order to prevent operators to break into the safety zone and stop the machine. Or, on an AGV application, the warning signal can be used to slow the vehicle down, so that a possible further break of the safety zone will not force it to stop abruptly, thus reducing the mechanical wear of the AGV.

The profiles of the controlled areas, as well as all the other configurable parameters, are programmable through a dedicated user interface software, installed on a laptop or PC and connected with the scanner via a serial interface.

The Laser Scanner is also able to automatically detect the controlled area by means the teach-in function.

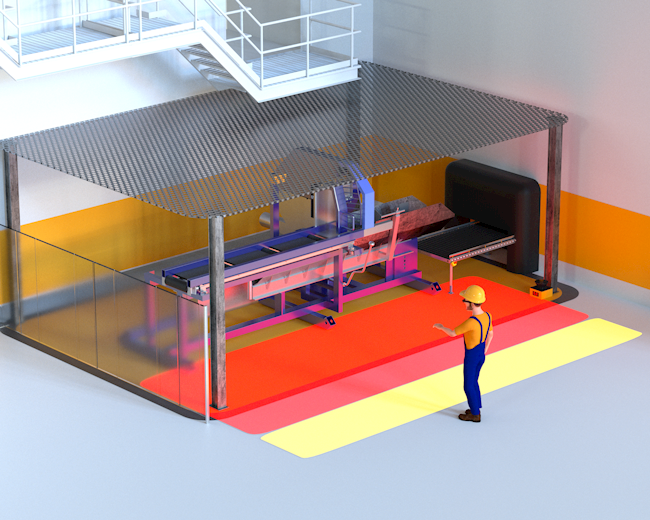

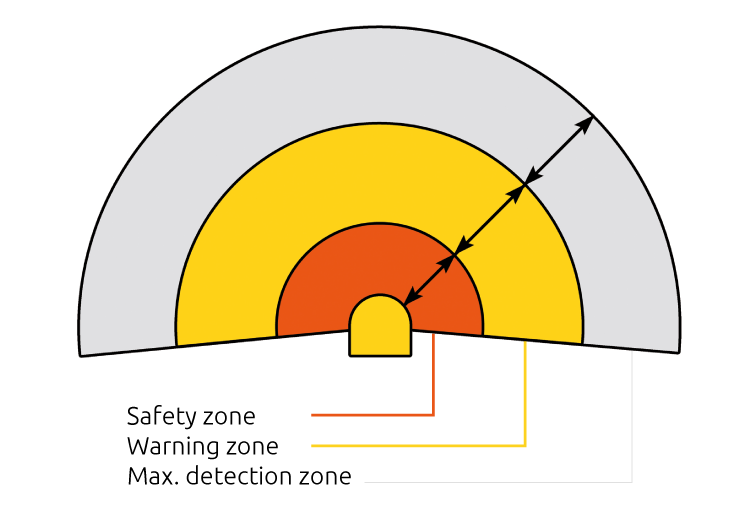

Controlled areas

Safety zone

This is the effective protection zone, in which the laser scanner assures the detection of any obstacle having a minimum reflectivity to infrared light of 1.8%. This means any human body in any possible clothing.

The occupation of this zone causes the switching of the two safety outputs that control the emergency stopping of the machine.

The shape of the zone can be programmed according to the application requirements.

Warning zone

This is the zone in which the laser scanner is able to detect the presence of an obstacle approaching the safety zone.

The occupation of this zone causes the switching of the auxiliary output that can be used to activate light or sound signals or in order to slow down the hazardous movement.

This zone is generally larger than the safety zone. In this case also the shape of the zone can be programmed according to the application requirements.

Advantages of the laser scanner

- No receiving and reflecting elements

- Simple programming of differently-shaped controlled areas

- Monitoring and protection of large areas

- Horizontal mount for the detection of the body in a dangerous area

- Vertical mount for the detection of hands and arms or for the detection of the body in access control

- Use on moving vehicles (AGVs)

- Measurement of object size, shape and position

- Fast and reliable installation

Applications

Area control

Example of an horizontally mounted protective field permanently monitored by Pharo. In this way a larger area can be monitored through the detection of the lower limbs of the body.

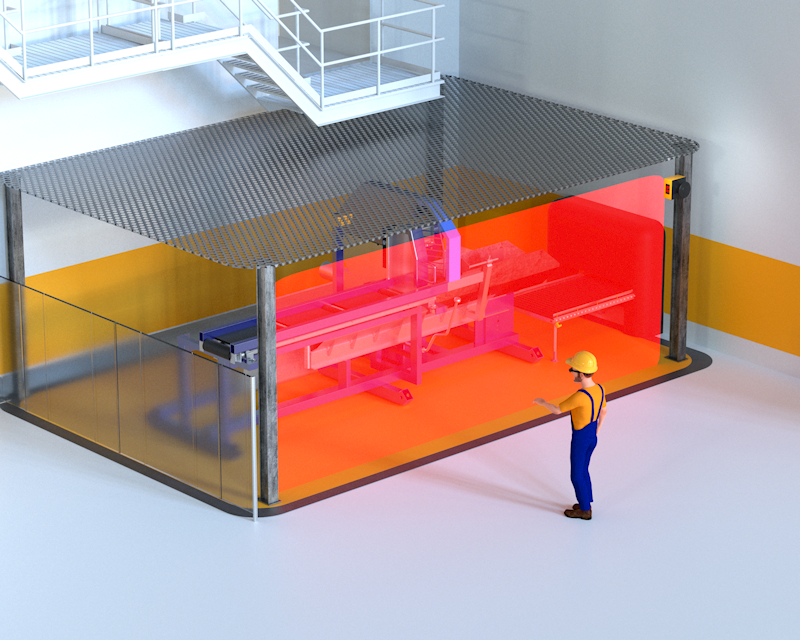

Access control

If the controlled plane is installed in a vertical position, even very large accesses can be protected. Hands, arms or the whole body can be detected, depending on the chosen resolution.

Note: the contour detection is mandatory for the vertical mount / accesscontrol applications.

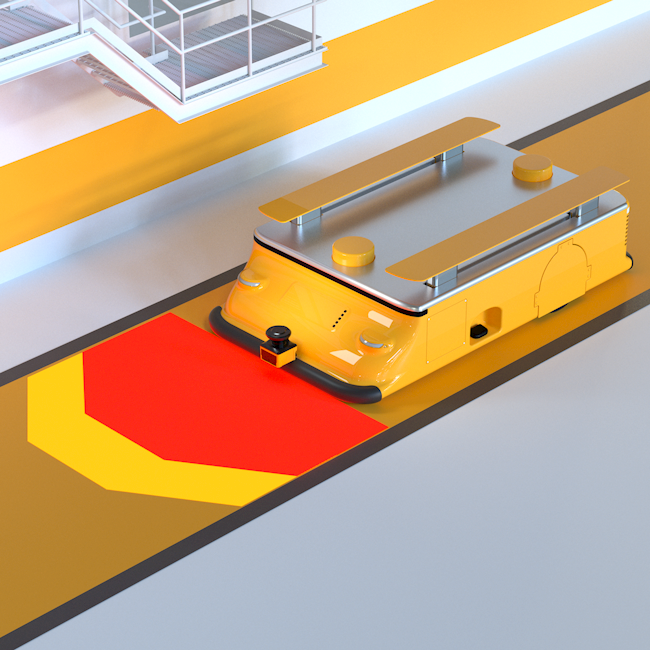

Protection of Automatic Guided Vehicles (AGV)

The vast size of the controlled area allows the AGV to travel at higher speeds with respect to bumper protection.

The warning area permits speed reduction in the presence of obstacles.

The data measured by the sensor can be sent to the vehicle on the serial interface and used as navigation aid.

Dimensional measurement

The sensor is first of all a measurement device. Therefore, the measurement data of the surrounding environment, which are always available during operation, can also be used for object profile, position and dimensions measurement in industrial automation.