Manufacturing

Inductive safety sensors

The PI-Safe inductive safety sensors can generally be installed in all those applications that require a non-contact and safe detection of a metal object.

We are analyzing two of the most common applications:

- Detection of the correct and safe position of a rotary table in an assembly machine

- Safety control of the position and stroke of a bin tipper

Discover the product

Inductive safety sensors

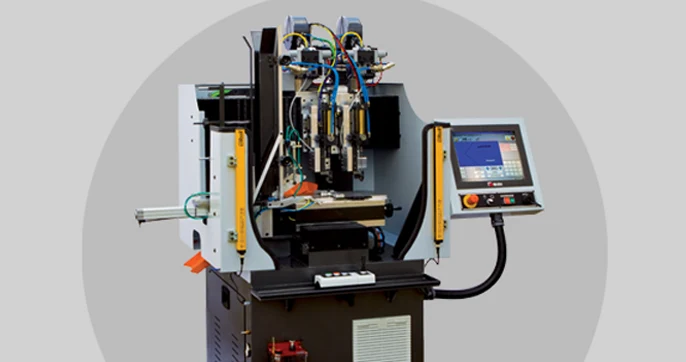

Woodworking machines

The most popular applications are the following: Drilling machines, Lathes, calendula burs. Milling machines

These machines operate with different tools controlled and selected by an Automatic Tool Changer (ATC). It is therefore possible to operate the machines with or without operator intervention.

For this type of machines, as specified by the standards, the control of the safety speed of each tool during operations is mandatory.

Discover the product

Mosaic – Speed Monitoring

Machine for footware industry

List of machines for the footwear industry using light curtains, magnetic switches and the safety controller

Discover the product

Magnus – Magnetic sensors

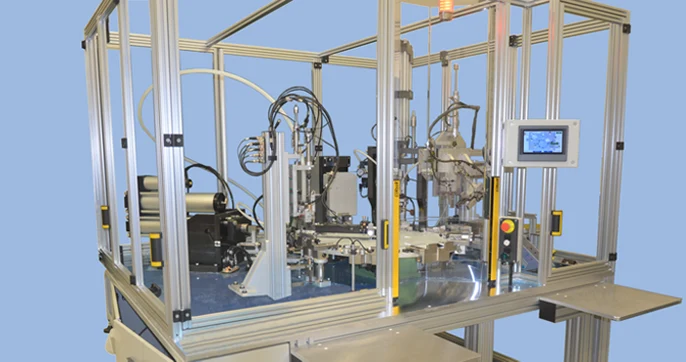

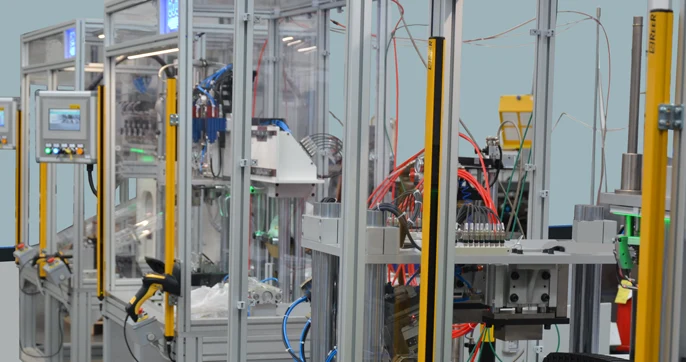

Automatic assembly line

Protection of assembly lines with different levels of interaction with operators.

The operator must enter the work pieces and start the machine using a start command. During the machine cycle the operator gate is protected by light curtains.

The height of the light curtains protects the entire working areas.

The height of the light curtains prevents from reaching the dangerous point also if leaning above the last beam of vertical light curtain.

Discover the product

Mosaic Safety controller