Automatic Vehicle Classification Systems – Toll gates

Typical methods for collecting tolls on the paid road sections and highway are:

- Manual collection – Is the simplest form of toll collection, in which a collector operating from a booth collects the toll.

- Automatic toll collection via vending machines allow collection of several methods of payments: coins, tokens, debit cards, and credit cards.

- Electronic toll collection (ETC) system – Able to electronically charge a toll to an established customer account.

In this application note we will consider two subsystems for automated toll payment that use ReeR safety light curtains and measurement and automation light curtains as sensors:

- Automatic Vehicle Classification System (AVC).

- Electronic Toll Collection System (ETC)

Automatic Vehicle Classification (AVC) consist of sensors (lasers, optoelectronic light curtains, cameras or intelligent detector loops embedded in the pavement) installed in the toll lanes to detect and classify the vehicles for proper tolling.

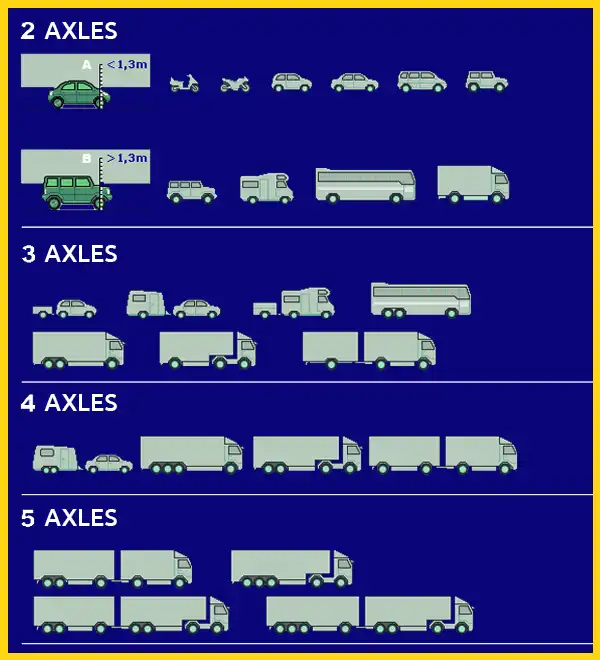

On the paid road sections. For example highway sections of “Autostrade per l’Italia” and almost all other Concessionaires, the vehicles classification is carried out on the basis of physically measurable elements such as:

- The shape – i.e. the height of the vehicle on the perpendicular of the front axle – For 2 axle vehicles (classes A, B)

- The number of axles – For vehicles or trains with more than two axles (classes 3, 4, 5).

Similar classifications are used in other Extra European countries such as China, India.

Electronic Toll collection (ETC) is a system enabling collection of toll payments electronically, allowing toll collection and traffic monitoring.

ETC makes high speed tolling operations possible as drivers don’t have to stop and make the payments. ETC also reduces financial vulnerability and frauds as the automatic payments don’t require any cash handling. This system includes Bar Coding, online payment, Digital payment Processing, RFID (Radio Frequency Identification) etc.

Use of Micron measurement and automation light curtains in AVC systems

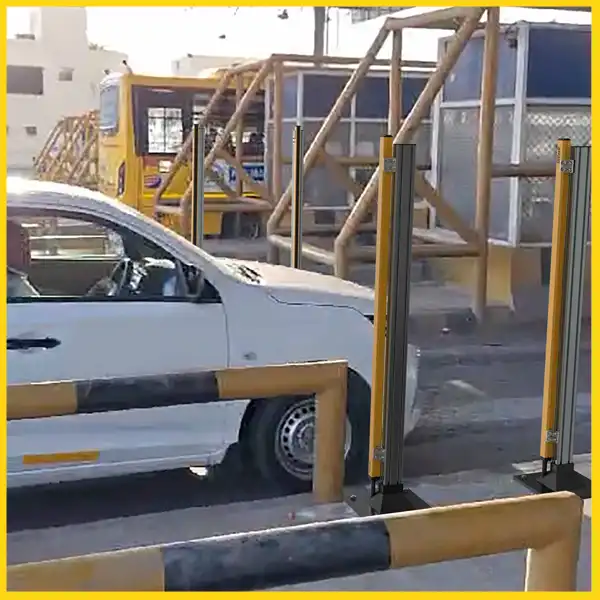

In this system for automatic vehicle classification (made in India by Metro Infrasys Pvt Ltd.), Micron opto-electronic light curtains are used for detecting the data of transiting vehicles and cross-checking the tolls detected.

When the vehicle passes the barrier, after the toll is paid the automatic classification system creates the vehicle profile and automatically the management software generates a report to cross-check the data.

The Micron measurement light curtains is therefore a key element in the evaluation of the correct toll rate as it ensures accurate detection and classification of vehicles.

Micron Measurement light curtains allows the following measurement:

- Vehicle separation – Detection of the individual vehicle that cross the light curtains

- Optical axle counting (vehicle axle counting)

- Height measurement (height detection on the first axles)

The system reliability is 99.95% for vehicles transiting at 90 Km/h, 99.00% for vehicles passing through 120 Km/h.

The minimum detection distance of vehicles is 10 mm. The system allows to detect the tow hitch.

This system is flexible in design and supports changing classification schemes.

The classification is based on axles, distance between axles, single and double wheels and multiple vehicle heights.

Micron measurement light curtains, placed at the exit of each toll payment lane, through the RS 485 serial interface can be connected to a controller and transmit the beams status:

- FBO – First beam obstructed

- LBO – Last beam obstructed

- CBO – Central beam obstructed *

- NBO – Number of beams obstructed

- NCBO – Maximum number of consecutive beams obstructed *

- BNO – Beam non obstructed

* If more than one zone is obstructed, the data refer to the zone with the highest number of obstructed beams.

ReeR Solution

Micron measurement and automation light curtains

Light curtains for industrial and civil applications where it is necessary to detect, measure, and recognise objects.

Micron B

Models MI B equipped with an RS 485 serial interface with programmable functions and two programmable digital outputs. Ideal for dimensional measurement, detection of object profile and position

- Controlled heights: 150 … 3000 mm. In this case up to 2 m models are used

- Programming interface: USB interface on M5 4-pole connector.

- Possibility of connection of up to 3 Micron B light curtains as nodes of an RS 485 serial line for simultaneous detection of multiple dimensions and complex measurements.

- Max. Range 10 m

- In this application: 10 mm or 30 mm beam spacing. All micron range: 5 mm , 25 mm, 50 mm and 75 mm beam spacing

Use of EOS Safety light curtains in ETC systems

Electronic Toll Collection System (ETC) uses:

- Transponders (installed on vehicles)

- Wireless communication (RFID Sensors) for reading the trasponders

- Sensors on the payment lane for detecting the passage of vehicles

- A computerized system (hardware and software) for unique identification of each vehicle, electronic toll collection, general monitoring of the vehicle, traffic, and for data collection

EOS safety light curtains are used here as sensors for vehicle detection.

When the vehicle passes through the safety light curtains controlled area, the OSSD outputs of the safety light curtain switch to “low” logic level indicating to the system a vehicle presence. This will activate the wireless RFID sensors to read the transponder on board the vehicle; thus identifying the vehicle and collecting the toll. The system for reading the transponder will only work if the vehicle passes through at a speed of less than 40 km/h.

Another pair of EOS safety light curtains is used to monitor vehicle speed. It is checked how long it takes the vehicle to pass between barriers.

In this way the speed is monitored.

If transit between light curtains takes longer than the set time (speed less than 40 km/h), the barriers activate the RFID system to read the transponder.

If the detected speed is above 40 km/h, the signal to activate the RFID system for reading the transponder will not be sent.

As a result, the vehicle passageway will remain closed and special signage will give directions to the driver.

In this application, EOS safety light curtains are placed at the entrance of the toll lane to detect the presence of the vehicle and enable reading of the transposnder status on the vehicle.

This detection is used by the ETC System to direct the approaching vehicle to the appropriate lane for toll collection.

ReeR Solution

EOS2 Safety light curtains

EOS2 is a compact safety light curtain range with competitive performance and innovative features. Includes models with integrated safety functions such as self-monitoring static outputs, control of external contactors (EDM), and selectable automatic or manual restart.

2 safety PNP static outputs. Easy connection and installation thanks to the M12 connectors and the use of unshielded cables up to 100 meters.

EOS2

EOS2 903 A safety light curtains are used for this application.

- Automatic Start/Restart

- 30 mm resolution

- Connections and configurations through M12 5-pole connectors. Unshielded cables up to 100 meters long can be used to connect the light curtain.

- Protected heights: 160 mm … 2260 mm. In this application a light curtains with 910 mm protected height is used

EOS4

Light Curtains For Industrial Safety Applications

Protect workers and your plant and machinery safely and efficiently with ReeR safety light curtains.

Our range of solutions covers every safety need in the field of industrial automation.

Safety Light curtains are electro sensitive devices using one or more light beams, emitted by an Emitter and received by a Receiver, to create an intangible controlled area.

With this solution, you can ensure a safe working environment for your staff, preventing accidents and injuries.