Micron measurement light curtains in automated car wash Systems

The Challenges of Automated Tunnel Car Wash Systems

Tunnel car wash systems are one of the most popular solutions for providing fast and effective service to a large number of vehicles, differing in shape and size. Their modular design and sequential operation make it possible to optimize washing time, providing thorough and customized cleaning. However, to maintain high standards of quality and productivity, these systems face several challenges, including:

- The need to fit a wide range of vehicles, including irregular shapes or accessories such as skiboxes and bike racks;

- Ensuring the safety of the washing process, avoiding vehicle damage or malfunctions;

- Optimize detergent and resource consumption, reducing costs and environmental impact.

Reer Safety’s Solution: Micron Measurement Light curtains

Reer has responded to these specific challenges with Micron MI B measurement barriers and RS485 serial output, an advanced technology designed to improve the productivity and efficiency of tunnel car washes.

These measuring barriers enable:

- Accurately recognize vehicle contours: Micron barriers detect shape and size in real time, automatically adapting the wash program to the specific vehicle, such as the position of the roller brushes;

- Ensure safe and customized washing: By transmitting detailed data to the system controller, errors and selections incompatible with the vehicle structure are avoided;

- Reduce operating costs: Accurate metering enables optimization of detergent and resource use, contributing to environmental sustainability and an important cost reduction.

The use of photocells along the route, positioned at successive modules, completes the offering by ensuring timely control of any misalignment or incorrect vehicle positions.

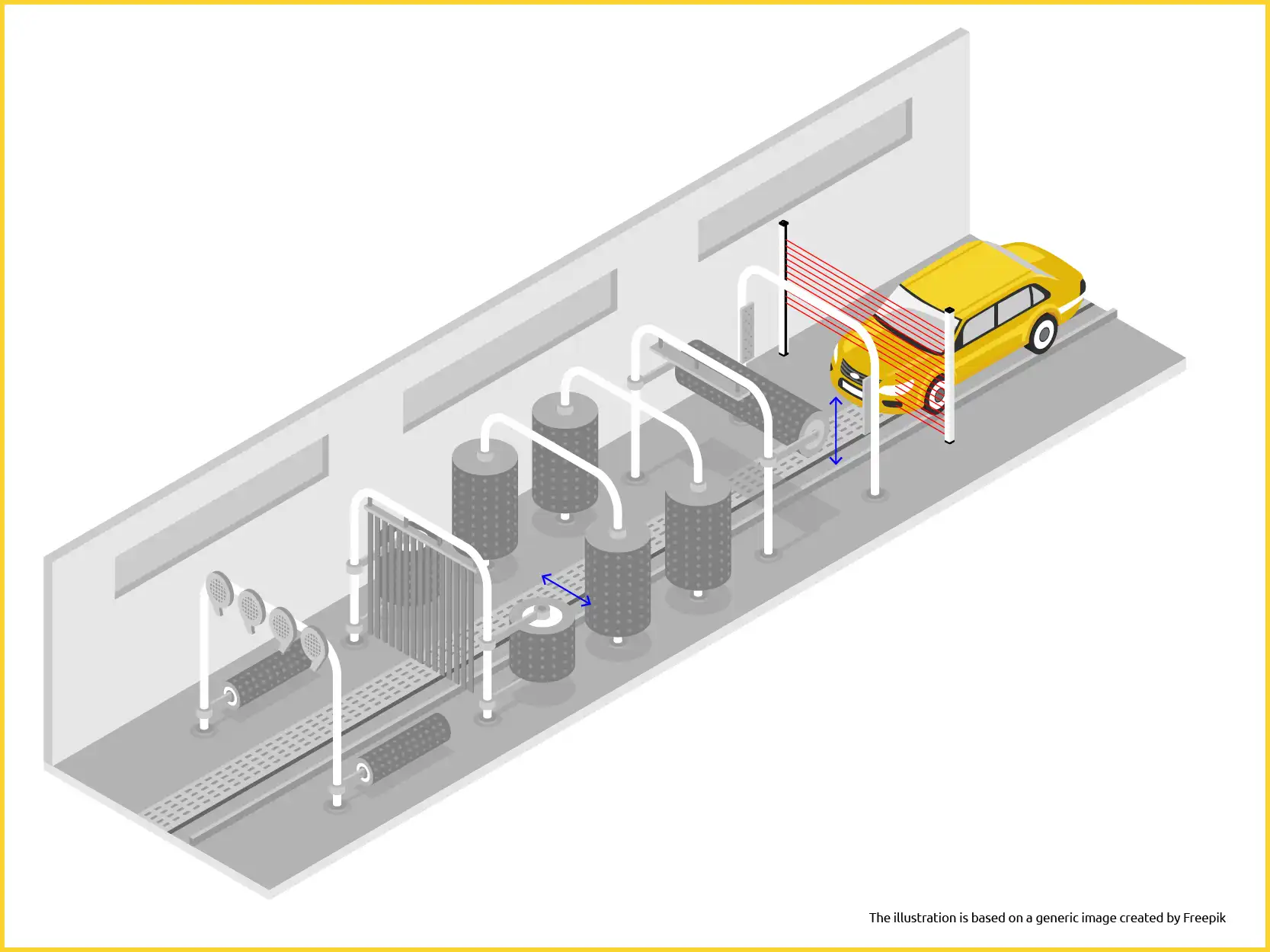

How Do Micron Barriers Work?

Micron measurement barriers, integrated into wash tunnels, transmit through the RS 485 serial interface fundamental information such as:

- First and last occupied beam (FBO and LBO);

- Center occupied beam (CBO)

- Total number of occupied beams (NBO);

- Max number of consecutive occupied beams (NCBO).

- Unoccupied beam (BNO).

With these features, it is possible to:

- Detect vehicles with irregular shapes;

- Monitor any misalignments or misplacements;

- Prevent malfunctions and improve the efficiency of the wash cycle.

A key aspect for applications of this type is that Reer’s Micron barriers are available in WTF and WTHF versions, which are IP69K certified to provide maximum resistance to water jets, steam and harsh operating environments. The H versions also include an internal heating system, ideal for applications in harsh climate environments.

ReeR Solution

Micron measurement and automation light curtains

Light curtains for industrial and civil applications where it is necessary to detect, measure, and recognise objects.

Micron B

Models MI B equipped with an RS 485 serial interface with programmable functions and two programmable digital outputs. Ideal for dimensional measurement, detection of object profile and position

- Controlled heights: 150 … 3000 mm. For this application, we recommend heights from 1500 mm

- Programming interface: USB interface on M5 4-pole connector.

- Possibility of connection of up to 3 Micron B light curtains as nodes of an RS 485 serial line for simultaneous detection of multiple dimensions and complex measurements.

- Max. Range 10 m

With Micron measuring light curtains, Reer offers a state-of-the-art solution for optimizing the operation of tunnel car washes. Accuracy, reliability, and durability make Micron an indispensable choice for those looking to improve productivity, reduce operating costs, and offer high-quality service.

Contact us today for more information and learn how ReeR solutions can help you take your automated carwash facility to the next step!

ReeR, your future’s safe!