Safety solutions in Explosive Atmospheres – ReeR Safety

ATEX-Certified Safety controllers: The Mosaic RV Range

The term ATEX (Atmosphère Explosibles) refers to the European certification required for all equipment sold within the European Union that is intended for installation in potentially explosive environments. Safeguarding industrial facilities in such conditions presents unique challenges for both machinery and operators.

The ATEX framework is based on the European directive 2014/34/EU that requires companies to assess whether their facilities include areas at risk of explosion.

HazLoc (Hazardous Location) certification, on the other hand, primarily applies to North America and Canada and aims to control explosion risks in certain atmospheres. This certification is evaluated by UL in compliance with standards UL 121201:9ED 2017-09-15 and CSA C22.2 NO. 213-17, covering electrical equipment for use in hazardous (classified) locations.

Industries such as chemical, petrochemical, pharmaceutical, food, and maritime often face these risks, making it essential to rely on manufacturers who provide reliable, modular, and regulation-compliant solutions.

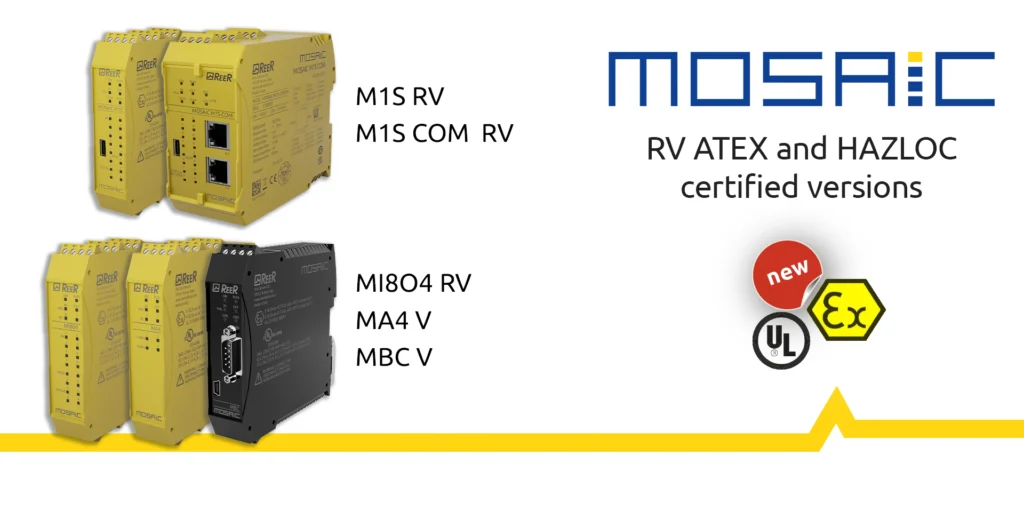

The Mosaic RV range from ReeR Safety addresses these needs, offering advanced safety control solutions for complex environments. With ATEX Zone 2 and HazLoc certifications, as well as compliance with international standards, Mosaic RV ensures safety, reliability, and flexible integration in any type of facility. The RV versions include the main units M1S RV and M1S COM RV, along with expansion modules MI8O4 RV, MA4 V, and MBC V.

Ideal applications

The versatility of the Mosaic RV range makes it suitable for a wide range of industrial applications:

- Chemical and Petrochemical Plants: Providing safe control in environments with explosive gases or vapors.

- Industrial Automation: Ideal for regulated sectors such as pharmaceuticals and food, where safety and productivity must go hand in hand.

- Maritime and Offshore Applications: Designed to withstand harsh marine environments.

The Mosaic RV Range: A Versatile and Complete Safety Solution

The Mosaic RV range integrates seamlessly with the main and expansion modules of the broader Mosaic series, offering unparalleled flexibility:

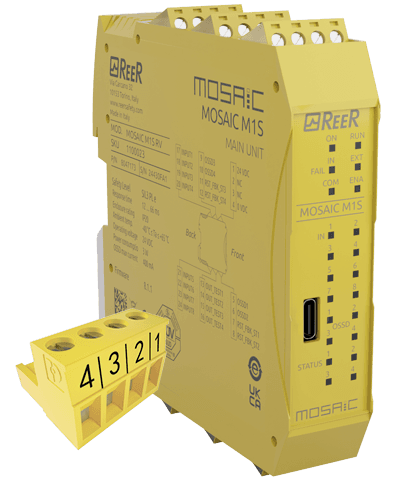

- M1S RV: Advanced master unit for comprehensive safety control, compatible with a wide range of expansions.

- M1S COM RV: The most advanced master unit, featuring dual RJ45 interfaces for Field-bus connections and remote management, ideal for complex and highly integrated systems.

- MI8O4 RV: Expansion module with digital inputs and outputs.

- MA4 V: Expansion modules for analog inputs.

- MBC V: Field-Bus interface modules for diagnostics and data transmission.

ReeR Solution

The Mosaic RV Range

- ATEX Zone 2 Certification: Compliant with Directive 2014/34/EU and international standards, they are designed to operate in environments with the presence of explosive gases, vapors or mists;

- HAZLOC Certification: Compliant with UL 121201:9ED 2017-09-15 and CSA C22.2 NO. 213-17, ensuring safety for electrical equipment in hazardous locations;

- Wide Operating Temperature Range: Designed to operate reliably in extreme conditions, from -40°C to +65°C, without compromising performance or durability;

- Protective Coating for Marine Environments: The conformal coating shields electronic components from humidity and atmospheric agents, extending device longevity;

- Modularity and Flexibility: The main and expansion modules integrate seamlessly, enabling custom configurations through proprietary MSD software tailored to specific application needs.

Learn More

For more details on the Mosaic range and its applications, visit our website at reersafety.com or contact our experts. With Mosaic, safety and innovation come together to successfully address the challenges of industrial automation.

ReeR, your future’s safe!

Important Note

Using the Mosaic RV range in high-risk environments, such as those with potentially explosive atmospheres, requires a thorough analysis of the specific application context. Always ensure the correct integration of the product within your industrial system, in compliance with applicable regulations and technical specifications. To guarantee maximum safety and functionality, consult our experts for a tailored assessment.