Safety in Woodworking Machinery

Speed Control as a synonym for Safety

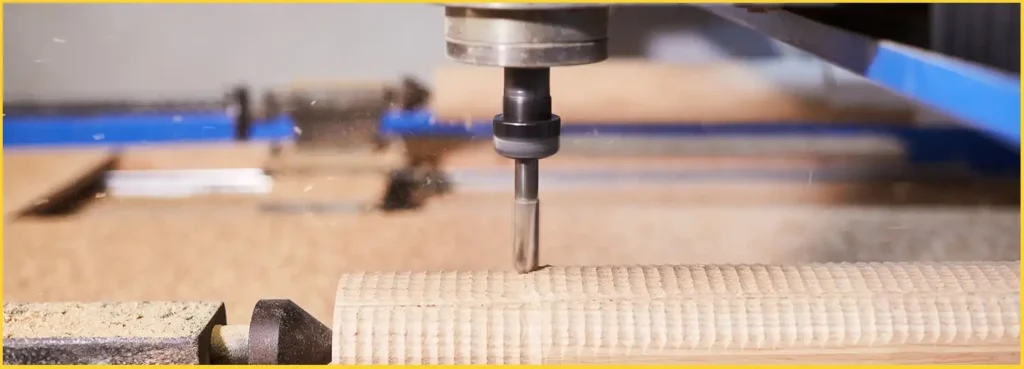

In the woodworking industry, advanced machines such as milling machines, lathes and numerically controlled (CNC) drilling machines ensure high precision and productivity. These are machine tools whose movements are controlled by an integrated PLC. However, tool speed management and control are critical aspects of maintaining high safety standards, protecting operators, the working environment and machine integrity.

High-speed operations require the utmost accuracy in parameter setting to ensure that the tool speed is always optimal with respect to the material and machining characteristics. Excessive speed can in fact reduce efficiency, increase tool wear and pose a safety risk, while inadequate speed can compromise finish quality and slow production.

Regulatory Requirements for Safety in Woodworking Machinery.

ISO 19085-1 and 19085-3 standards establish specific requirements for the design and risk reduction measures related to the use of woodworking machinery, paying particular attention to operating speed. Here are the main normative points:

- Tool Identification – A tool recognition system must be in place to ensure the correct selection of speed and operating mode, although without the need to reach a certain Performance Level (PLr);

- Maximum Speed Control – It is required that machines be equipped with a tool speed control system that automatically limits the RPM, preventing exceeding 10% of the maximum allowable speed. This system requires a Performance Level c (PLc) to ensure operational safety;

- Automatic Monitoring and Stopping – When the tool exceeds the preset speed beyond the prescribed limits, the control system must stop motion immediately;

Additional Safety Requirements – For numerically controlled machines, the operator must confirm the maximum tool speed parameters displayed and stored in the control system. In the case of preset speeds or specific tools, such as drilling spindles, active speed control is not required.

Why Speed Control is Essential

Speed control in woodworking machines is essential to ensure safety and efficiency. Incorrect tool speed can cause:

- Overheating of tools, reducing tool life.

- Overwork and inefficiency in the cutting process.

- Tool damage and poor material finish.

An analysis of the different manufacturers of this type of machine found that the tools can operate in a range of 5 speeds (9000, 12000, 18000, 24000 and 30000 run per minute, or rpm) and in some cases even with 10000, 15000 and 20000 rpm, reaching 8 different speeds.

Therefore, controllers are needed to monitor up to a maximum of 8 different speeds.

ReeR Spa’s answer for safe speed control

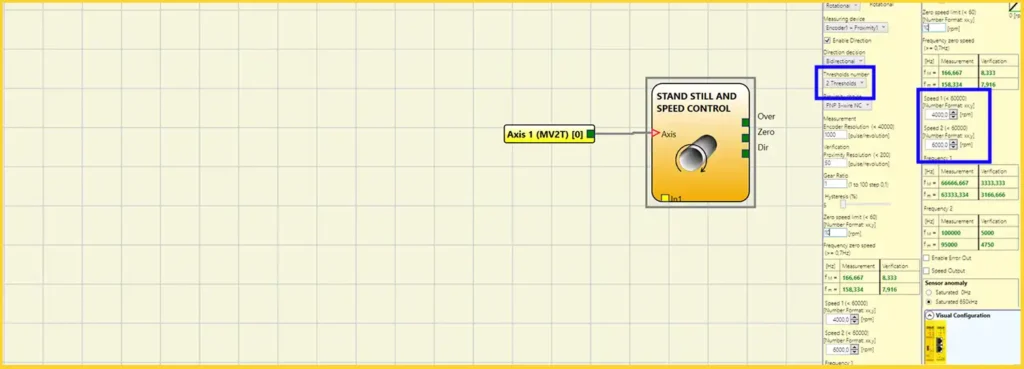

To ensure high safety standards in woodworking machines, ReeR Spa offers Mosaic MV speed safety control modules, capable of monitoring up to 8 different speeds on multiple axes, which can be configured according to operational needs.

The Mosaic Safety Designer (MSD) software integrates the Speed Control module, which safely monitors tool speed and ensures that it does not exceed set limits. When the measured speed exceeds the preset threshold, the module generates a “FALSE” (0) output signal, automatically stopping the machine to avoid damage and dangerous situations. Conversely, as long as the speed remains below the set threshold, the output remains on “TRUE” (1), allowing the machine to operate normally.

Depending on the requirements of the machining operation, the Speed Control block allows parameter configuration regarding the number of speed thresholds–from 1 up to a maximum of 8–to suit the specific needs of different operations. Each threshold can be set with a maximum speed value, and the machine will automatically stop if it is exceeded.

With this control, woodworking machines not only comply with safety regulations, but also ensure a safe working environment, maintaining optimal performance and protecting both operators and equipment.

ReeR Solution

MOSAIC speed monitoring expansion cards (MV series)

Safety speed monitoring (up to PL e) for: Zero speed control, Maximum speed control, Speed range control, Direction.

MOSAIC MV1

Input for 1 incremental encoder (TTL, HTL or SIN/COS) and 2 proximity switches.

4 maximum-speed thresholds.

MOSAIC MV2

Input for 2 incremental encoders (TTL, HTL or SIN/COS) and 2 proximity switches.

8 maximum-speed thresholds.

Ensure that every operation is carried out safely, maintaining high performance and protecting your personnel and equipment.

Contact us and find out how speed control, through advanced solutions like ReeR Spa’s Mosaic MV and MSD, can make a difference in your woodworking machines.

ReeR, your future’s safe!